Everyone is familiar with Flexible Metal Conduit, but you are not familiar with their environment. The environmental factors of the application of metal hoses are mainly considered in the following five aspects: When selecting metal hoses, they must be prepared according to the tempering of metal hoses under high temperature working pressure at high temperatures. Correct the coefficient and reduce its extra pressure to ensure safety under operating conditions.

Flexible metal conduit is stainless steel. Reactive anions (such as sulfur and chloride ions) generally exist in the medium are easy to passivate the stainless steel film. In small metal corrosion holes, it is the active center of pitting corrosion. The potential of the metal surface of the corrosion hole is negative, and the potential of the metal surface of the corrosion hole is the outer, outer and inner holes. In the passivation condition, it constitutes a living miniature galvanic corrosion cell.

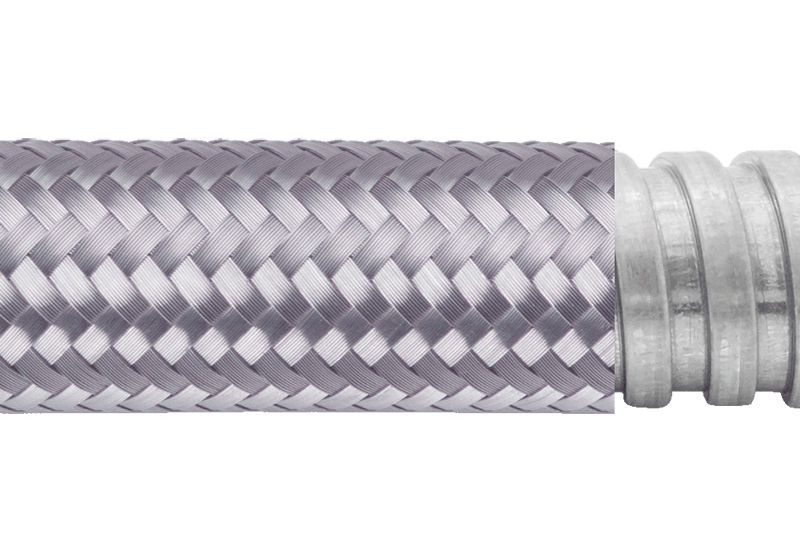

Flexible Metal Conduit EMI Proof-EU

The anode current density is high, and the etching hole is deepened rapidly. The strength of corroded metal hoses decreases and simply causes failure under internal pressure and tensile load. Therefore, metal hoses with a corrosive environment should be selected and added with protective measures to improve the corrosion resistance.

Under dynamic conditions, metal hoses are often damaged by fatigue cracks under the effect of cyclic loading. This damage is normal. In order to extend the service life, the hose should be planned correctly, the device is correct, and there is no deformation and other additional stress.

The water hammer is a transient process of pressure caused by sudden changes in the activity of the medium and changes in fluid momentum in the pipeline. It is a special vibration phenomenon caused by the unstable activity in the tube. Pressure waves that rise and fall sharply through a pipe occur similar to the noise that occurs when a pipe is hammered with a hammer. When water hits, the impact of the tortuous section of the pipe is greater. Therefore, the user should follow the requirements of the operating procedures, such as slow heating, voltage stabilization, falling instantaneous flow and pressure changes, to prevent water shock.

Flexible Metal Conduit Exporter tells us what to pay attention to when installing stainless steel metal hoses:

1. The chloride ion content in the medium is ≤25PPM.

2. The surface of the metal hose should be protected from welding spatters and arc burns. The metal hose is usually protected with neutral wet asbestos.

3. When choosing a flange connection hose, it is best to choose a metal hose with a loose flange at one end.

4. Never twist the metal conduit for installation.

5. It should not bend along the root of the hose, and there should be no dead bend.

6. Mechanical damage to the flange sealing surface is strictly prohibited.

7. Do not use chlorine-based cleaning agents or wire brushes to remove dirt from metal hoses.

Our company also has Flexible Metal Conduit EMI Proof-EU on sale, welcome to consult.

评论

发表评论